10mm Copper Bonded Conductor -Pune

or 4 interest-free installments by Afterpay. More Info

Description

Description

10mm Copper Bonded Conductor Manufacturer in Pune – Earthing Mart

Overview – Pune Conditions

Pune features mixed black cotton soil and rocky terrain, with resistivity ranging from 30–120 Ω-m. Heavy industrial belts (MIDC, automotive, manufacturing) require mechanically strong conductors capable of handling high fault currents.

Product Overview & Working Principle

What is a 10mm Copper Bonded Conductor?

A 10mm copper bonded conductor consists of a high-tensile low-carbon steel core metallurgically bonded with 99.9% pure electrolytic copper. Unlike copper-clad or coated wires, the molecular bond ensures no peeling, cracking, or galvanic separation, even under thermal cycling and fault conditions.

How It Works in Earthing Systems?

-

The steel core provides mechanical strength and deep-driving capability.

-

The thick copper layer ensures excellent conductivity and corrosion resistance.

-

When installed in earth grids, vertical electrodes, or ring mains, it dissipates fault and lightning currents safely into soil, stabilizing touch and step potentials.

Technical Specifications (10mm Copper Bonded Conductor)

| Parameter | Specification |

|---|---|

| Nominal Diameter | 10 mm |

| Core Material | Low carbon steel |

| Copper Purity | ≥ 99.9% electrolytic copper |

| Copper Bonding | Molecular (continuous metallurgical bond) |

| Copper Thickness | As per IEC 62561 |

| Tensile Strength | ≥ 600 N/mm² |

| Electrical Conductivity | High (stable under fault currents) |

| Standard Lengths | Coils / cut lengths (project-specific) |

| Operating Environment | Indoor / Outdoor / Buried |

| Expected Service Life | 30–40 years (soil dependent) |

Performance & Engineering Advantages

Proven Performance in Indian Conditions of 10mm Copper Bonded Conductor

Low Earth Resistance: Optimized conductor geometry delivers reliable resistance values in 10–200 Ω-m soils.

-

Corrosion Resistance: Copper layer resists chlorides (coastal belts) and acidic soils during monsoons.

-

High Fault Current Capacity: Safely carries short-circuit and lightning surge currents without deformation.

-

Mechanical Robustness: Steel core prevents stretching or breakage during trenching and backfilling.

Standards & Compliance

| Standard / Authority | Compliance |

|---|---|

| IS 3043 | Code of Practice for Earthing |

| IEC 62561 | Lightning Protection Components |

| CEA Guidelines | Electrical Safety & Earthing |

| CPWD Specifications | Govt. & PSU projects |

| DISCOM Requirements | Utility-approved earthing |

*All products supplied via EarthingMart are accompanied by test certificates, material traceability, and GST invoices.

Applications & Use Cases

-

-

Automotive Manufacturing Plant, Chakan MIDC

-

Project Type: Automotive OEM Facility

-

Challenge: Seasonal soil expansion, heavy machinery fault current

-

Solution: Grid earthing with 10mm copper bonded conductor and exothermic joints

-

Result:

-

Earth resistance maintained below 1 Ω

-

Improved equipment grounding reliability

-

Compliance with CEA safety audit

-

-

-

Why Buy from EarthingMart? (Supplier Advantage)

| Parameter | EarthingMart | Typical Market Vendors |

|---|---|---|

| Engineering Support | ✔ Dedicated earthing experts | ✖ Limited |

| Standards Compliance | ✔ IS & IEC documented | △ Often unclear |

| Stock Availability | ✔ Ready stock | ✖ Made-to-order |

| Pan-India Delivery | ✔ Yes | △ Regional |

| Bulk Project Pricing | ✔ Transparent | ✖ Inconsistent |

| Documentation | ✔ Datasheets & test reports | △ Partial |

| After-Sales Support | ✔ Technical assistance | ✖ Minimal |

Installation & Maintenance Guidance (Best Practices)

Installation Guidelines

-

Lay conductor in trenches (minimum 600 mm depth) or as per design.

-

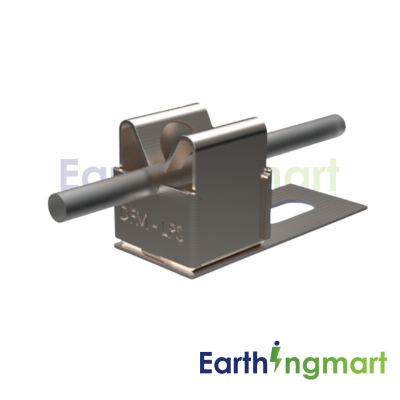

Use exothermic welding or approved clamps for joints—avoid loose mechanical connections.

-

Ensure proper backfill (bentonite/earthing compound) in rocky or dry soils.

-

Maintain continuous loops for ring earthing systems.

Maintenance Recommendations

-

Periodic earth resistance testing (annual or pre-monsoon).

-

Visual inspection of accessible joints.

-

No routine replacement required due to copper-bonded construction.

FAQs – 10mm Copper Bonded Conductor

1. Is copper bonded conductor better than GI for Pune industries?

Yes. It avoids corrosion caused by soil moisture variation.

2. Can it withstand heavy fault currents from motors?

Yes. Steel core provides high tensile and fault endurance.

3. Is it suitable for MIDC projects?

Yes. Commonly specified in MIDC and automotive EPC tenders.

4. Does EarthingMart offer bulk supply in Pune?

Yes. Project-based pricing and fast dispatch supported

5. What jointing method is recommended?

Exothermic welding is preferred for permanent, low-resistance joints.

7. Is it suitable for solar plants?

Yes. Widely used in utility-scale and rooftop solar projects across India.

8. Do you provide bulk pricing?

Yes. EarthingMart offers project-based bulk pricing and logistics support.

9. Is technical support available?

Yes. Dedicated earthing experts assist with design and product selection.

Delivery Info

- Standard and Express delivery services are available for all items.

- Shipping costs are calculated at the checkout page (after delivery option & destination confirmation).

- Tracking is available for all delivery options.

- Items are delivered during standard business hours.

Reviews

There are no reviews yet.