Description

Description

Earth Fixed Point – Engineered Reference Earthing Solution by EarthingMart

An Earth Fixed Point (EFP) is a permanent, standardized, and measurable earthing reference point used to interconnect all earthing electrodes, conductors, lightning protection systems, and equipotential bonding networks within an electrical installation. Designed for Indian soil resistivity conditions (10–200 Ω-m) and harsh operating environments, the Earth Fixed Point by EarthingMart provides a single, testable, low-impedance reference node that ensures electrical safety, fault current dissipation, and long-term compliance with Indian and international standards.

Built for EPC contractors, MEP consultants, Grade-A electrical contractors, solar plant developers, infrastructure companies, and industrial earthing specialists, this solution delivers engineering reliability over marketing claims—with measurable performance, documented compliance, and site-proven durability.

Primary CTA: Request Best Price Quote

Secondary CTA: Talk to Earthing Expert

Product Overview & Working Principle

What Is an Earth Fixed Point?

An Earth Fixed Point is a dedicated earthing junction and inspection node that acts as the central reference for the entire earthing system of a facility. Unlike isolated electrodes or scattered test links, an EFP consolidates:

-

Earth electrodes (rod, plate, chemical, strip)

-

Equipment earthing conductors

-

Lightning down conductors

-

Neutral grounding (where applicable)

-

Surge protection earthing

into one engineered, accessible, and testable point.

Working Principle

-

Multiple earth electrodes are installed as per soil resistivity and fault level.

-

All earth conductors terminate at the Earth Fixed Point using corrosion-resistant clamps.

-

The EFP equalizes potential across all earthing paths, minimizing step and touch voltage.

-

During faults or lightning events, current disperses uniformly into the soil, avoiding localized heating and impedance rise.

-

Periodic testing is performed directly at the EFP without system shutdown.

This approach is critical in monsoon-prone, coastal, rocky, and high-resistivity soils commonly found across India.

CTA: Download Technical Datasheet

Technical Specifications – Earth Fixed Point

| Parameter | Specification |

|---|---|

| Product Type | Earth Fixed Point / Earthing Reference Node |

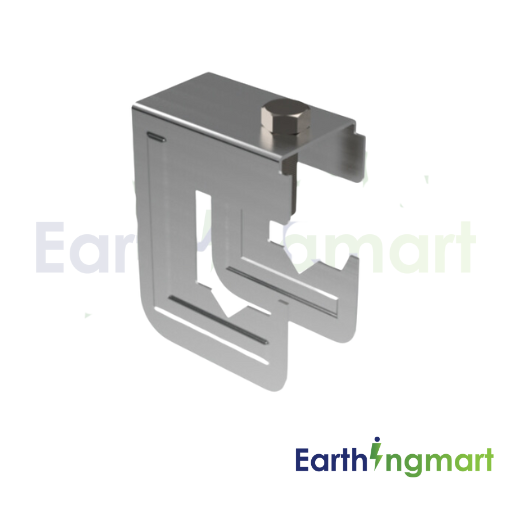

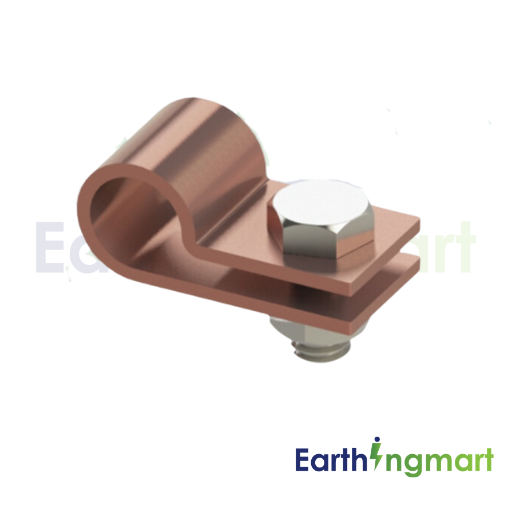

| Construction | Copper / GI / SS Termination Assembly |

| Rated Fault Current | Up to 50 kA (1 sec) – configurable |

| Operating Resistance Target | ≤ 1 Ω (system dependent) |

| Compatible Conductors | Copper strip, GI strip, copper cable |

| Termination Type | Bolted / Exothermic weld compatible |

| Corrosion Protection | Hot-dip galvanization / Copper bonding |

| Inspection Access | Ground-level inspection pit |

| Installation Environment | Indoor / Outdoor / Subsurface |

| Design Life | 25+ years |

Performance & Engineering Advantages

1. Stable Low Earth Resistance

-

Maintains consistent resistance even during dry seasons

-

Suitable for high-resistivity soils (rocky & arid zones)

2. Reduced Step & Touch Voltage

-

Centralized equipotential bonding minimizes human risk

-

Critical for substations, data centers, solar plants, and hospitals

3. Long-Term Corrosion Resistance

-

Designed for coastal and high-moisture environments

-

Prevents joint failure due to galvanic corrosion

4. Simplified Testing & Maintenance

-

Single-point testing saves time during statutory audits

-

No need to disconnect multiple electrodes

5. Scalable for Large Campuses

-

Ideal for industrial parks, airports, metros, refineries, and SEZs

CTA: Project Support Request

Standards & Compliance

Applicable Indian & International Standards

| Standard | Compliance Scope |

|---|---|

| IS 3043 | Code of practice for earthing |

| IEC 62561 | Lightning protection system components |

| CEA Regulations | Electrical safety & grounding |

| CPWD Specifications | Government infrastructure projects |

| DISCOM Guidelines | Utility and grid interconnection |

EarthingMart ensures documentation-ready compliance, simplifying approvals for consultants, inspectors, and DISCOM authorities.

Applications & Real-World Use Cases

1. Solar Power Plants (Utility & Rooftop)

Case Example – 50 MW Solar Plant, Rajasthan

High soil resistivity (>120 Ω-m) required a clustered electrode network connected via a central Earth Fixed Point, reducing earth resistance from 3.8 Ω to 0.9 Ω within three weeks.

2. Electrical Substations

Used as a main grounding node to interconnect grid, transformer neutrals, structures, and lightning masts.

3. Industrial Facilities

Ensures safe dissipation of fault current for heavy machinery, VFDs, and HT panels.

4. Commercial Buildings & IT Parks

Acts as a reference earthing hub for power, data, and lightning protection systems.

5. Infrastructure Projects

Mandatory in metro rails, airports, oil & gas terminals, and large government projects.

CTA: Bulk Order Enquiry

Why Buy Earth Fixed Point from EarthingMart

Supplier Comparison

| Parameter | EarthingMart | Local Fabricators | Generic Traders |

|---|---|---|---|

| Engineering Design | ✔ Yes | ✖ No | ✖ No |

| Standards Compliance | ✔ Documented | Partial | Unverified |

| Soil-Specific Customization | ✔ Yes | ✖ No | ✖ No |

| Technical Support | ✔ Pre & Post Sales | Limited | None |

| Pan-India Delivery | ✔ Yes | Regional | Regional |

| Bulk Project Pricing | ✔ Available | Inconsistent | Limited |

EarthingMart operates as an engineering-led online marketplace, not just a reseller—bridging design, supply, and technical accountability.

Request: Talk to Earthing Expert

Installation & Maintenance Guidance

Installation Best Practices

-

Locate EFP at a central, accessible point

-

Interconnect minimum 2–6 earth electrodes based on fault level

-

Use exothermic welding or approved bolted joints

-

Provide inspection pit with identification marking

Maintenance Recommendations

-

Measure earth resistance twice annually (pre & post monsoon)

-

Inspect joints for corrosion or loosening

-

Maintain test records for statutory audits

EarthingMart provides installation drawings, BOQs, and method statements on request.

Frequently Asked Questions (FAQs)

1. What is the purpose of an Earth Fixed Point?

It provides a single, measurable reference for all earthing and lightning protection systems.

2. Is Earth Fixed Point mandatory as per IS 3043?

IS 3043 strongly recommends centralized and testable earthing points for large installations.

3. Can it be used in high-resistivity soil?

Yes, it is specifically designed for Indian soil conditions up to 200 Ω-m.

4. What resistance value can be achieved?

Typically ≤1 Ω, depending on electrode design and soil treatment.

5. Is it suitable for solar power plants?

Yes, it is widely used in utility-scale and rooftop solar projects.

6. How is it different from a normal earth pit?

An Earth Fixed Point is a system-level reference, not just an electrode.

7. Does it support lightning protection integration?

Yes, lightning down conductors can be terminated at the EFP.

8. What materials are available?

Copper, GI, and stainless steel configurations.

9. Is testing possible without shutdown?

Yes, testing is designed to be non-intrusive.

Trust & Commercial Signals

-

✔ Ready Stock Availability

-

✔ Pan-India Delivery

-

✔ Bulk & EPC Pricing Support

-

✔ GST Invoice & Compliance Documents

-

✔ Technical Datasheets & Drawings

-

✔ After-Sales Engineering Support

Delivery Info

- Standard and Express delivery services are available for all items.

- Shipping costs are calculated at the checkout page (after delivery option & destination confirmation).

- Tracking is available for all delivery options.

- Items are delivered during standard business hours.

Reviews

There are no reviews yet.