Hot dip Galvanized Strips manufacturer in Bengaluru

or 4 interest-free installments by Afterpay. More Info

Description

Description

Hot Dip Galvanized Strips for Earthing Systems | EarthingMart

Hot Dip Galvanized Strips are a core component of high-performance earthing and grounding systems used across Indian infrastructure, industrial, utility, and renewable energy projects. Designed to withstand Indian soil resistivity conditions ranging from 10–200 Ω-m, these strips provide a low-impedance, corrosion-resistant current dissipation path essential for personnel safety, equipment protection, and statutory electrical compliance.

At EarthingMart, we supply engineering-grade Hot Dip Galvanized (HDG) steel strips manufactured to meet IS 3043, IEC 62561, and CEA / CPWD requirements, making them suitable for monsoon-prone, coastal, rocky, and high-resistivity soils across India.

Primary Use: Horizontal earthing conductors, earth grids, ring earthing, and interconnections for large electrical installations.

Product Overview & Working Principle

What is a Hot Dip Galvanized Strip?

A Hot Dip Galvanized strip is a mild steel flat strip coated with a thick zinc layer (≥70–100 microns) by immersion in molten zinc. This metallurgical bonding provides long-term corrosion protection, even in aggressive soil and moisture environments.

How It Works in Earthing Systems

-

The strip is laid horizontally below ground level (typically 600–1000 mm).

-

It forms an equipotential earth grid or ring, connected to:

-

Earth electrodes (GI pipes, rods, copper bonded rods)

-

Structures, panels, transformers, and lightning down conductors

-

-

The zinc coating acts as a sacrificial anode, protecting steel and ensuring stable earth resistance over decades.

This makes HDG strips ideal for large-area fault current dissipation in Indian climatic conditions.

Technical Specifications – Hot Dip Galvanized Strip

| Parameter | Specification |

|---|---|

| Base Material | Low Carbon Mild Steel |

| Coating Process | Hot Dip Galvanization |

| Zinc Coating Thickness | 70–100 microns (as per IS 4759) |

| Standard Widths | 25 mm, 32 mm, 40 mm, 50 mm, 75 mm |

| Standard Thickness | 3 mm, 5 mm, 6 mm |

| Length Supply | Cut length / Coil form |

| Electrical Conductivity | ~10–12% IACS |

| Tensile Strength | 370–510 MPa |

| Operating Temperature | -40°C to +80°C |

| Expected Service Life | 25–40 years (soil dependent) |

CTA: Download Technical Datasheet

Performance & Engineering Advantages

1. Superior Corrosion Resistance

-

Thick zinc layer resists:

-

Monsoon water logging

-

Coastal salinity

-

Industrial chemical exposure

-

-

Proven performance in high-moisture and red laterite soils common in India.

2. Cost-Effective for Large Networks

-

Lower lifecycle cost compared to copper strips

-

Ideal for solar plants, substations, factories, and infrastructure projects

3. Mechanical Strength

-

Withstands soil pressure, trench compaction, and construction activity

-

Suitable for direct burial without additional conduits

4. Stable Earthing Performance

-

Maintains consistent earth resistance in 10–200 Ω-m resistivity soils

-

Performs reliably in rocky and dry zones when combined with earth enhancement compounds

Standards & Compliance

Applicable Indian & International Standards

| Standard | Compliance Description |

|---|---|

| IS 3043 | Code of Practice for Earthing |

| IS 4759 | Hot Dip Galvanized Coatings |

| IEC 62561-2 | Earthing and Bonding Components |

| CEA Regulations | Safety Requirements for Electrical Installations |

| CPWD / DISCOM Specs | Approved for Govt & Utility Projects |

All HDG strips supplied by EarthingMart are supported with mill test certificates and coating compliance reports.

Applications & Use Cases

1. Solar Power Plants (MW Scale)

Case Example – 25 MW Solar Plant, Rajasthan

-

HDG strips used as ring and mesh earthing

-

Combined with GI electrodes and enhancement compound

-

Achieved earth resistance <1 Ω in high-resistivity desert soil

2. Electrical Substations & Switchyards

-

Transformer neutral grounding

-

Control room earth grids

-

Lightning protection bonding

3. Industrial & Manufacturing Facilities

-

Process plants

-

Data centers

-

Heavy electrical machinery grounding

4. Commercial & Infrastructure Projects

-

Airports, metros, highways

-

IT parks and high-rise buildings

-

Oil & gas installations

CTA: Project Support Request

Why Buy Hot Dip Galvanized Strips from EarthingMart?

Supplier Comparison

| Criteria | EarthingMart | Local Traders | Generic Steel Suppliers |

|---|---|---|---|

| Engineering Validation | ✔ Yes | ✖ Limited | ✖ No |

| Standards Compliance | ✔ IS / IEC | ⚠ Partial | ✖ Unverified |

| Zinc Thickness Control | ✔ Certified | ✖ Inconsistent | ✖ Unknown |

| Project Support | ✔ Yes | ✖ No | ✖ No |

| Bulk Pricing | ✔ Yes | ⚠ Limited | ⚠ Limited |

| Pan-India Delivery | ✔ Yes | ✖ Local | ⚠ Selective |

EarthingMart Advantage: An engineering-led online marketplace purpose-built for earthing and lightning protection systems, not a generic metal supplier.

Request : Bulk Order Enquiry

Installation & Maintenance Guidance of GI Strips

Installation Best Practices

-

Trench depth: 600–1000 mm

-

Lay strips straight with smooth bends (avoid sharp angles)

-

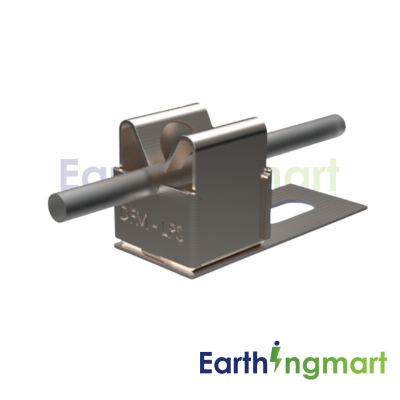

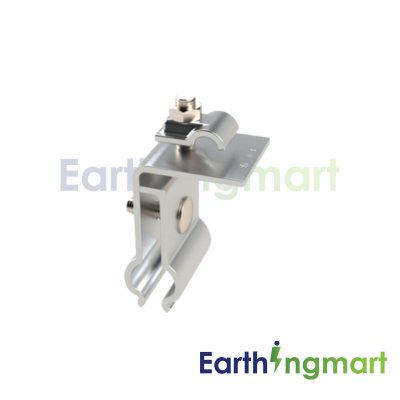

Use HDG clamps or exothermic welding

-

Interconnect with electrodes at defined grid spacing

-

Backfill with native soil or enhancement compound as per soil resistivity

Maintenance Recommendations

-

Visual inspection during major shutdowns

-

Periodic earth resistance testing

-

Check mechanical joints in high-vibration areas

Designed for low-maintenance, long-life performance in Indian environments.

FAQs – Hot Dip Galvanized Strips

1. What is the difference between HDG strip and GI strip?

HDG strips have thicker, uniform zinc coating offering longer corrosion resistance than pre-galvanized GI strips.

2. Are HDG strips suitable for coastal areas?

Yes, they perform reliably in saline and humid coastal conditions.

3. Can HDG strips replace copper strips?

For large-area earthing networks, HDG strips offer a cost-effective alternative with adequate performance.

4. What sizes are commonly used in substations?

40×6 mm and 50×6 mm are widely used in Indian substations.

5. Do you supply as per IS 3043?

Yes, all strips comply with IS 3043 earthing practices.

6. How long do HDG strips last underground?

Typically 25–40 years depending on soil aggressiveness.

7. Can these be used in solar plants?

Yes, extensively used in MW-scale solar and wind projects.

8. Do you provide test certificates?

Yes, zinc coating and material test certificates are available.

9. Is bulk pricing available for EPC projects?

Yes, EarthingMart offers project-based bulk pricing.

Delivery Info

- Standard and Express delivery services are available for all items.

- Shipping costs are calculated at the checkout page (after delivery option & destination confirmation).

- Tracking is available for all delivery options.

- Items are delivered during standard business hours.

Reviews

There are no reviews yet.