Description

Description

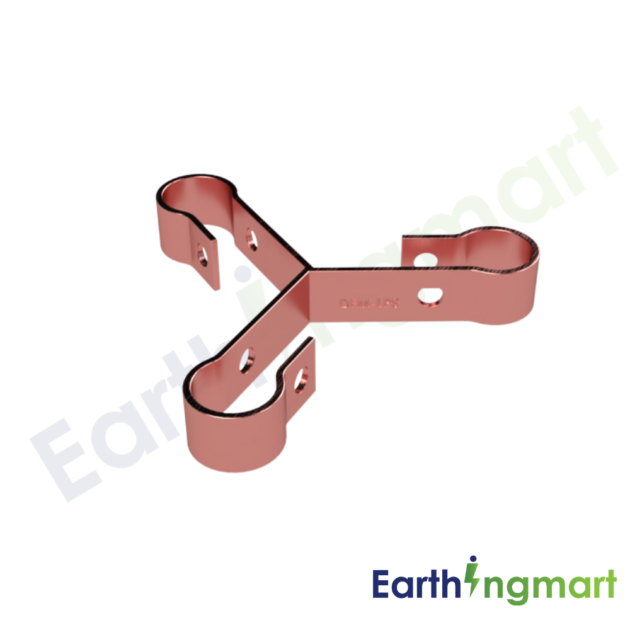

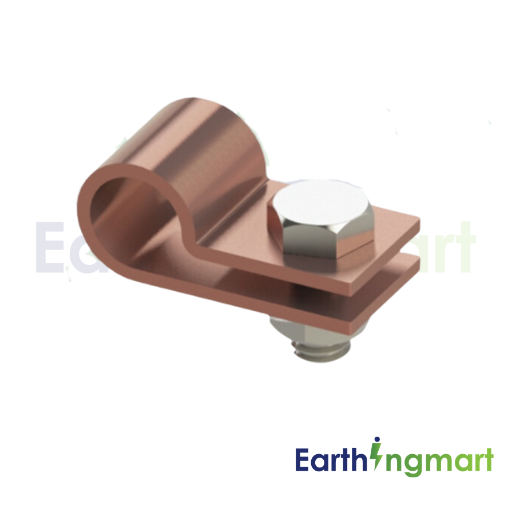

U Bolt Clamp for Lightning Protection System | EarthingMart

U Bolt Clamp by EarthingMart is a mechanically robust fastening solution engineered for secure termination and bonding of down conductors in lightning protection and earthing systems. Designed specifically for Indian climatic and soil conditions (10–200 Ω-m), this clamp ensures low-contact resistance, vibration resistance, and long-term mechanical stability across monsoon-prone, coastal, industrial, and high-resistivity terrains.

Used extensively by EPC contractors, MEP consultants, Grade-A electrical contractors, earthing companies, solar developers, and infrastructure projects, Earthingmart U Bolt Clamps are built to comply with IS 3043 and IEC 62561 requirements for lightning protection system components.

Request Best Price Quote | Talk to Earthing Expert

Product Overview & Working Principle of U Bolt Clamp

A U Bolt Clamp is a mechanical connector used to firmly bond round or flat conductors to structures, electrodes, pipes, or support members within a lightning protection system (LPS). It consists of a U-shaped threaded bolt, saddle plate, and high-torque nuts that apply uniform clamping pressure on the conductor.

How the U Bolt Clamp Works

-

The lightning down conductor (GI / copper / aluminium) is placed against the structure or electrode.

-

The U-bolt wraps around the conductor and support member.

-

Nuts are tightened to a specified torque, ensuring gas-tight metal-to-metal contact.

-

This minimizes contact resistance and prevents loosening due to vibration, thermal expansion, or wind loads.

This simple but critical component ensures continuity, equipotential bonding, and safe dissipation of lightning current into the earthing network.

Download Technical Datasheet | Bulk Order Enquiry

Technical Specifications – U Bolt Clamp

| Parameter | Specification |

|---|---|

| Conductor Compatibility | 10 mm,-32mm round conductor |

| Material Options | Hot Dip Galvanized Steel / SS 304 / SS 316 |

| Finish | HDG (≥70 microns), Natural Stainless Steel |

| Fastener Type | Hex Nut with Spring / Plain Washer |

| Tensile Strength | > 350 MPa (HDG Steel) |

| Corrosion Resistance | Suitable for coastal & industrial zones |

| Operating Temperature | –10°C to +80°C |

| Installation Type | Above ground & below ground |

Performance & Engineering Advantages

EarthingMart U Bolt Clamps are engineered beyond generic hardware fasteners.

Key Engineering Benefits

-

Low Contact Resistance: Uniform pressure ensures stable electrical continuity

-

High Mechanical Strength: Withstands wind loads, cable tension, and vibration

-

Corrosion Protection: HDG and SS options for coastal, chemical, and humid regions

-

Thermal Stability: Maintains grip during temperature cycling common in Indian climates

-

Maintenance Friendly: Easy inspection and retightening without dismantling

Unlike improvised clamps, EarthingMart clamps are dimensionally matched to earthing conductors, avoiding strand damage or conductor deformation.

Request Best Price Quote | Project Support Request

Standards & Compliance

| Standard / Code | Compliance Details |

|---|---|

| IS 3043 | Code of practice for earthing – compliant bonding method |

| IEC 62561-1 | Lightning protection system components – connectors |

| IEC 62305 | System-level lightning protection compatibility |

| CEA Guidelines | Approved for power & substation earthing |

| CPWD / DISCOM | Suitable for government & utility projects |

All clamps are supplied with material test certificates (MTC) and batch traceability on request.

Applications & Use Cases (India-Focused)

Typical Applications

-

Lightning down conductor fixing on RCC & steel structures

-

Earthing conductor bonding in substations

-

Solar plant lightning protection networks

-

Industrial plant earthing grids

-

Commercial & high-rise buildings

Real-World Case Examples

-

100 MW Solar Plant, Rajasthan: SS 316 U Bolt Clamps used for down conductor fixing in high-resistivity (≈150 Ω-m) desert soil with extreme temperature variation.

-

Coastal Refinery, Gujarat: HDG clamps replaced with SS clamps to mitigate salt corrosion and ensure long-term continuity.

-

IT Park, Bengaluru: Used for lightning down conductor routing on façade steel members during monsoon-heavy conditions.

Why Buy U Bolt Clamp from EarthingMart?

| Criteria | EarthingMart | Generic Hardware Vendors |

|---|---|---|

| Designed for Earthing | ✔ Yes | ✖ No |

| IS / IEC Compliance | ✔ Documented | ✖ Rare |

| Corrosion Grade Options | ✔ HDG / SS 304 / SS 316 | ✖ Limited |

| Technical Support | ✔ Earthing Engineers | ✖ Sales Only |

| Bulk Project Pricing | ✔ Yes | ✖ Inconsistent |

| Pan-India Availability | ✔ Stocked | ✖ Location Limited |

Installation & Maintenance Guidance (Best Practice)

Installation Guidelines

-

Clean conductor surface before clamping

-

Ensure correct conductor size matching

-

Tighten nuts uniformly using calibrated torque wrench

-

Avoid over-tightening to prevent conductor damage

-

Apply anti-seize compound in coastal installations

Maintenance Recommendations

-

Visual inspection every 12 months

-

Retighten if looseness is observed

-

Replace clamps showing corrosion beyond limits

These practices align with IS 3043 maintenance guidelines for earthing systems.

FAQs – U Bolt Clamp for Lightning Protection

1. What is a U Bolt Clamp used for in lightning protection?

It mechanically bonds lightning down conductors to structures or electrodes ensuring electrical continuity.

2. Is U Bolt Clamp suitable for Indian soil conditions?

Yes, EarthingMart clamps are designed for 10–200 Ω-m soil resistivity and harsh climates.

3. Which material is best for coastal areas?

SS 316 is recommended for coastal and high-salinity environments.

4. Are these clamps compliant with IS 3043?

Yes, they meet bonding requirements defined under IS 3043.

5. Can it be used for solar plant lightning protection?

Yes, widely used in MW-scale solar PV projects across India

6. Does clamp size affect performance?

Yes, incorrect sizing increases resistance and mechanical failure risk.

7. Can it be installed below ground?

Yes, with appropriate corrosion-resistant material selection.

8. What documents are provided with supply?

GST invoice, test certificates, and technical datasheets.

9. How long is the service life?

25+ years for HDG, over 40 years for stainless steel variants.

Delivery Info

- Standard and Express delivery services are available for all items.

- Shipping costs are calculated at the checkout page (after delivery option & destination confirmation).

- Tracking is available for all delivery options.

- Items are delivered during standard business hours.

Reviews

There are no reviews yet.